GARANT Master burrs

The revolution in the world of burrs

Burrs are indispensable in metal processing. These sturdy tools improve surfaces, weld seams and fillet seams, and break edges – no matter whether they are used manually or on robots. Thanks to different shapes, sizes and their geometries and coating matched to the respective materials, our burrs can easily handle every task.

We have thoroughly tested our burrs to give you the best tool for every application and material. The extremely reduced vibrations of the GARANT Master burrs ensure top results, reduce scrap, and protect the health of your employees. For the development and improvement of the GARANT burrs, we have taken a very close look at problems in production.

Your challenges in practice:

- Vibrations: A high level of vibration creates poor surfaces and shortens tool life. In addition, it can affect the health of the user

- Wear: High wear and frequent replacement of the burrs generate unproductive times and lead to high costs

- Productivity: Low productivity fatigues the user and increases your process costs

Our solution: GARANT Master burrs

- Smoothest cutting action and optimum cutting capacity: Thanks to newly developed geometry and perfectly optimised helix angle

- Significant increase in performance: Due to the coating that is perfectly adapted to the material to be machined and an optimum ratio between stability and chip space

- Enhanced productivity: Very high removal rates combined with long tool life

The most powerful GARANT burrs:

The GARANT Master Uni burr is a real quantum leap. Thanks to significantly lower vibrations, more power, and higher metal removal rate, the new all-rounder offers up to 60% greater cutting performance! How does that come about? Simply thanks to completely new tooth geometry – a real system-based GARANT!

The challenge: vibrations.

However, the challenge is strong vibrations – disruptive to users and bad for the milling results. Thanks to our many years of experience in the market, we have succeeded in overcoming this challenge.

Our solution: a low-vibration all-rounder!

We have developed a new geometry, which enables the burrs to run considerably more smoothly, giving better guidance accuracy. Check out the GARANT Master Uni for hand tools and industrial robots – reliably manufactured from steel, stainless steel, aluminium and non-ferrous metals.

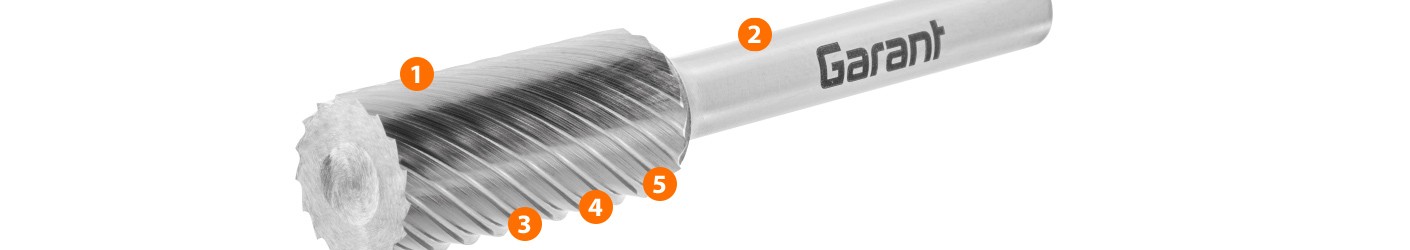

GARANT Master Uni: the all-rounder

1. Lowest vibration levels – maximum ergonomics

- Newly developed, innovative pitch

- Particularly ergonomic for the user

- Maximum smooth cutting despite high plunge depth

2. Secure retention in the collet

- Defined shank roughness prevents slipping

3. Maximum power

- Long tool life and

- High material removal thanks to newly developed tooth geometry and specially tailored edge honing

4. Available with a titanium coating

- Longer tool life

- Less heat input

- Better chip evacuation

5. Multi-talented and versatile

- Long tool life in a variety of materials

- Optimised carbide substrate for steel, stainless steel, aluminium and non-ferrous metals

- Available in 10 shapes

GARANT Master Steel: long tool life, smooth cutting action, high material removal rate

The standard for steel – exclusively from us.

The GARANT Master Steel series sets itself apart by its particularly high performance and low vibration during use. The extensive product range has the optimal solution for any machining task. This family allows you to machine all types of steel in a simple and inexpensive manner. A new unique geometry ensures significantly lower vibration and thus delivers significant advantages when it comes to application comfort, quality and tool life. It is designed for manual and industrial robot use.

1. Unbeatable on steel materials

- Long tool life with all steels.

- State-of-the-art substrate, optimised for an extremely long tool life.

- Available in 6 shapes.

2. With high-performance coating as standard

- Longer tool life.

- Less heat input.

- Better chip evacuation.

3. Lowest vibration levels, maximum ergonomics

- Newly developed, innovative pitch.

- Particularly ergonomic for the user.

- Maximum smooth cutting despite high plunge depth.

- The highest material removal rate.

4. Secure retention in the collet

- Defined shank roughness prevents slipping.

5. Maximum power

- Long working life.

- High material removal thanks to newly developed tooth geometry and specially tailored edge honing.

The GARANT Master Steel stands out in practical trials

The GARANT STEEL Cut convinces in the practical test

The GARANT Master Uni burrs are impressive during use

The new burrs sit quietly in your hand. Noticeably lower vibrations vividly demonstrate the advantages: easy to guide, higher material removal rate and significantly better surfaces – with longer tool life. This also applies of course when used on a machine and for all materials. A revolution made by GARANT.

Extended periods of vibration exposure can lead to damaged nerves, blood vessels and tendons in your fingers, hands and wrists. This reduces sensitivity, dexterity and strength. According to the Occupational Health and Safety Regulation, employers must ensure that employees are not exposed to vibration-related risks, or they must at least reduce these risks.

GARANT Master Inox: the quantum leap for machining stainless steel

Specially developed for stainless steel, the GARANT Master Inox

ensures the best results. It also provides the best possible ergonomics for the user.

It is designed for manual and industrial robot use.

1. Secure retention in the collet

- Defined shank roughness prevents slipping.

2. Lowest vibration levels, maximum ergonomics

- Newly developed, innovative pitch.

- Particularly ergonomic for the user.

- Maximum smooth cutting despite high plunge depth.

- The highest material removal rate.

3. Unbeatable on stainless steel materials

- Long tool life with all stainless steels.

- State-of-the-art substrate – optimised for an extremely long tool life.

- Available in 6 shapes.

4. Maximum power

- Long working life.

- High material removal thanks to newly developed tooth geometry and specially tailored edge honing.

5. With high-performance coating as standard

- Longer tool life.

- Less heat input.

- Better chip evacuation.

The GARANT Master Inox stands out from its rivals

The GARANT INOX Cut convinces in direct comparison

To the GARANT Master Inox burrs:

This chip guard for burrs with clear sight glass can be used on all common straight die grinders. Targeted chip evacuation for greater protection against chips flying up. It can be mounted quickly and easily using a fastening ring.

We have developed a new geometry, which enables the burrs to run considerably more smoothly, giving better guidance accuracy Discover the new GARANT Multi Cut now for manual use or use with industrial robots!

Tools In Action: GARANT Multi Cut burrs

Real innovation!

The new GARANT Multi Cut burrs run smoothly when used manually – the considerably reduced vibration brings clear advantages: good guidance accuracy, greater removal of material and much improved surfaces – with a longer tool life.

This also applies of course when used on a machine and for all materials. A revolution made by GARANT!

Outstanding surface results

To the GARANT Master Uni burrs:

To the GARANT Master Steel burrs:

GARANT Master Alu

The new Master Alu burrs help you reach your goal even faster. No compromises are made here in quality or in ergonomics for your employees. This burr not only cuts a fine figure in manual operation, but also in conjunction with an automation solution.

1. Lowest vibration levels, maximum ergonomics

- Newly developed, innovative pitch

- Particularly ergonomic for the user

- Maximum smooth cutting with maximum productivity

- Maximum material removal

2. Unbeatable on aluminium but also on other non-ferrous metals

- Long tool life

- State-of-the-art substrate optimised for an extremely long tool life

3. Maximum power

- Long working life

- High removal rates

- Outstanding process reliability

4. With high-performance coating as standard

- Adhesion and formation of built-up edges

are avoided effectively - Tool life is significantly increased again

5. Secure retention in the collet

- Defined shank roughness prevents slipping

To the GARANT Master Alu burrs:

GARANT Master Cast

Casting can often be a dusty and dirty affair, making it an unpleasant experience for both your employees and your components. With the innovative Master Cast product, we offer you an effective solution to significantly reduce your machining times, while protecting the health of your employees at the same time. By using Master Cast, you can complete the necessary work to the highest quality while benefiting from improved removal rates and a longer tool life. Discover the advantages of the Master Cast for yourself – your employees will thank you.

1. Maximum power

- Long working life

- High removal rates

- Outstanding process reliability

2. Lowest vibration levels, maximum ergonomics

- Newly developed, innovative pitch

- Particularly ergonomic for the user

- Maximum smooth cutting with maximum productivity

- Maximum material removal

3. Unbeatable in almost every cast

- Long tool life

- State-of-the-art substrate optimised for an extremely long tool life

4. Secure retention in the collet

- Defined shank roughness prevents slipping

5. With high-performance coating as standard

- Effectively protects the cutting edge from abrasive

wear caused by particles in the cast component