Get started with maximum efficiency. With Hoffmann Group Connected.

Automation does not have to be a huge project. The Hoffmann Group provides you with scalable solutions, ranging from partial automation with automatic loading and unloading to autonomous production with permanent process monitoring. Our connected tools, digital manufacturing and industrial vending solutions integrate seamlessly and optimize your processes. This makes efficiency improvements not just a goal, but a reality.

You have a challenge - we have the solution

"In the past, the simplest routine work used to take my time."

With automated processes such as vibratory finishing, also known as barrel finishing, you gain valuable time to use your specialists efficiently.

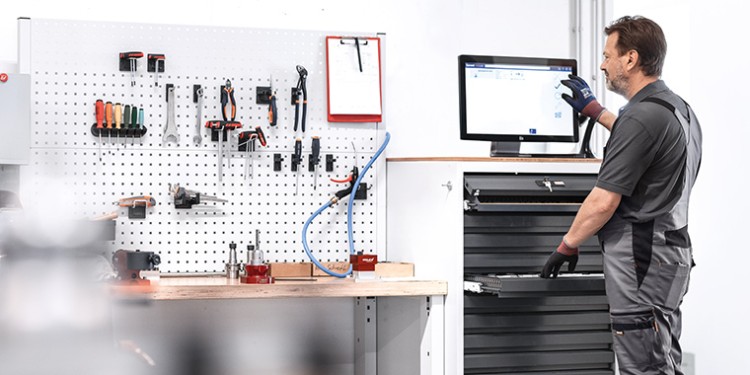

"How often is the tool you just need not there."

Access the right tool with vending systems: No search times, no frustration, no problems.

"I was often unsure if everything was going according to plan. If you ask, you are the annoying boss."

With digital manufacturing processes, you always have full transparency in real time: Without asking questions, without stress, without a bad image.