Version:

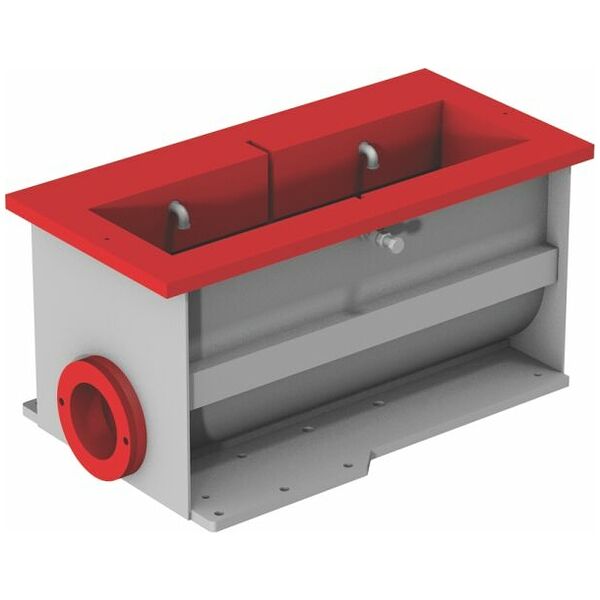

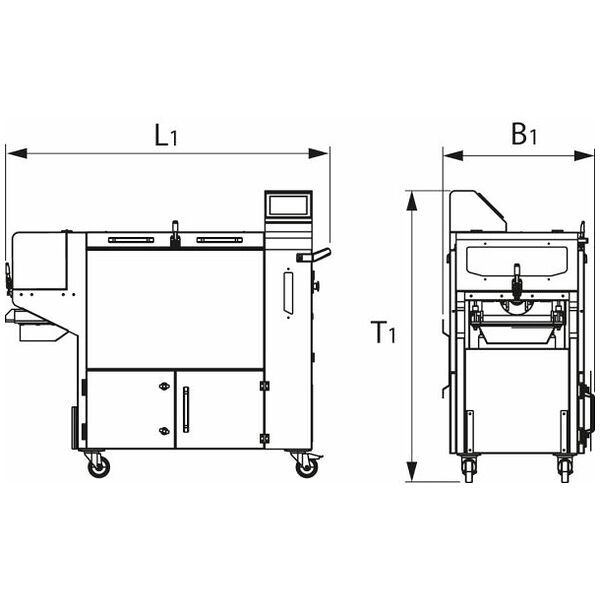

Mobile vibratory finishing machine GMT35 in

compact design, for automated finishing work on

small to medium batch sizes.- Powerful motor.

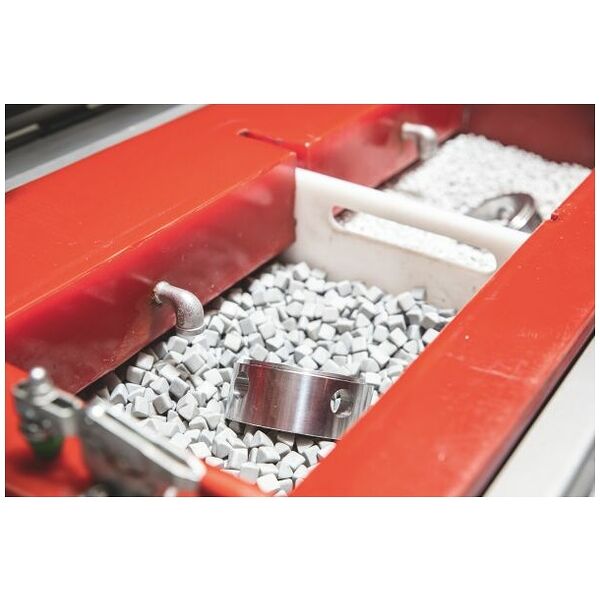

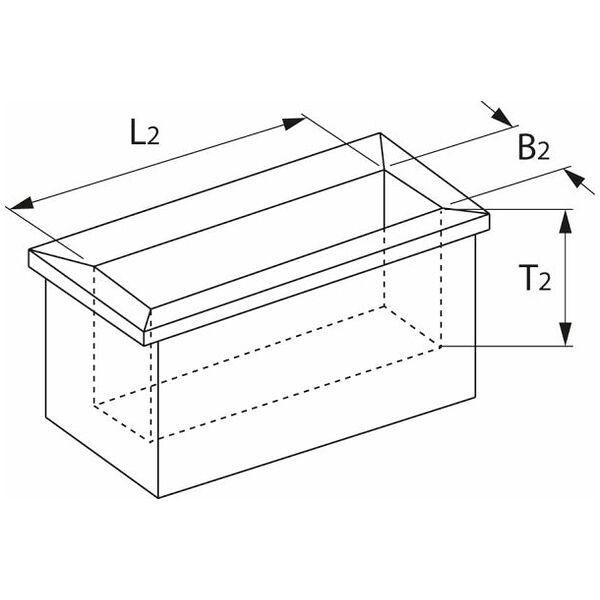

- Steel trough (35 l) with 15-mm polyurethane lining.

- Integrated separating station for automated separation of workpiece and grinding medium.

- Closed water circuit with wastewater treatment.

- Controlled via touch screen.

- Individual processing steps can be programmed.

- Machine with soundproof cover and lid.

- Rollers on the underside for easy transportation.

Application:

The preferred choice for deburring turned and milled parts and 3D-printed workpieces. Suitable for metals and plastics. This machine can also handle the subsequent steps of polishing and cleaning.

Supplied with:

1× vibratory finishing machine with integrated separating station, water circuit and PLC control, 1× transport trolley (No.

918558 TNB1), 2× small storage boxes (No.

964486 EF4220), 1× large storage box (No.

964486 EF4320), 2× dividers (aluminium, plastic), 2× measuring jugs, 1× hand shovel, 3× separating sieves with different hole patterns.

Note:

Unavailable in some countries. Express delivery not available

If, after vibratory finishing, you have very high requirements when it comes to cleaning and drying the components, the range of ELMA ultrasonic cleaning units from our catalogue of hand tools and measurement tools is recommended.

Warning:

Intended use- Surface finishing machine for surface processing such as deburring or polishing metal and plastic parts.

- Use only GARANT grinding bodies and compound.

- For work in indoor industrial environments. For use on dry solid floors.

- Use only when it is technically in good condition and safe to operate.

- Use only when correctly assembled and with safety devices and guards on the machine fully operational.

- Dispose of the compound properly.

Reasonably foreseeable misuse- Do not overload the machine.

- Do not apply mechanical loads to the touch screen.

- Do not use sharp objects for operating the touch screen.

- Do not use compounds incompatible with the workpiece materials.

- Feed the water-compound mixture in only via the water tank.

- Do not feed in any external liquids.

- Do not fill the circulation tank with an unsuitable ratio of water-compound mixture.

- Do not use any workpieces that are very sharply pointed, flammable or too large for the working container.

- Do not use in explosion hazard areas.

- Not for use in areas where the floor slopes upwards or downwards.

- Not for use in areas where high concentrations of dust, flammable gases, vapours or solvents are present.

- Do not make any unauthorised modifications.