{{ name }}

Article no. {{ combinedCodeWithHighlight }}

Article code:

EAN / GTIN:

Manufacturer number:

Cat. Nr.:

| maximum torque | 5 Nm | |

| Direction of tightening | For right- and left-hand tightening | |

| Torque measuring accuracy | ±4 % | |

| Exchangeable tool | Plug-in head | |

| Test certificate | Manufacturer’s test certificate | |

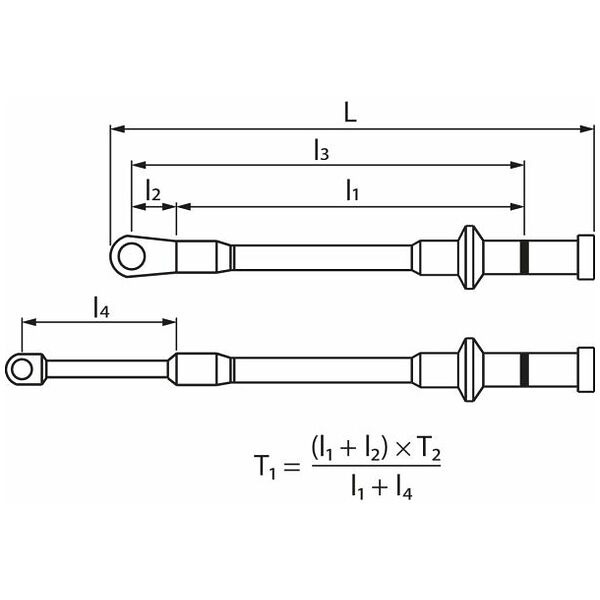

| Overall length L | 145 mm | |

| Torque range | 0.5 Nm - 5 Nm | |

| Weight | 220 g | |

| Adjusted reference dimension on the torque wrench [l2] | 17.5 mm | |

| Socket for plug-in head | 9×12 mm | |

| Release signalling | akustisk; haptisk | |

| Trigger principle | mechanical short-travel release | |

| Connection format | for plug-in heads (rectangular socket) | |

| Measurement technology | mechanical | |

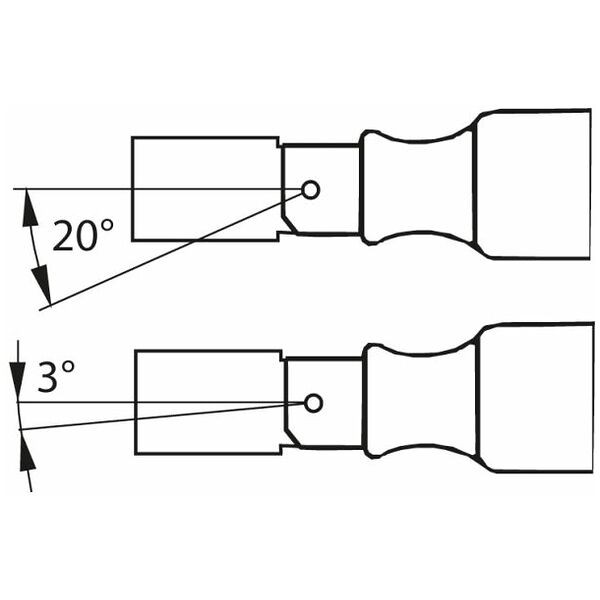

| Deflection function | yes | |

| Data can be recorded | no | |

| Setting the trigger value | without setting scale (requires torque analyser) | |

| Feedback | triggering | |

| Reversible reading | Nm | |

| Measurement process | Torque | |

| Adjustable trigger value | preset | |

| Standard | DIN EN ISO 6789 | |

| Lever length without plug-in head [l1] | 120 mm | |

| Lever length including factory calibration reference dimension [l3] | 137.5 mm | |

| Type of product | Torque Wrench |

| Article number | 657750 5 | |

| EAN / GTIN | 4045197514547 | |

| Manufacturer number | 657750 5 | |

| Manufacturer/responsible person | Hoffmann Supply Chain GmbH & Co. KG, Poststraße 15, 90471 Nürnberg, Germany, www.hoffmann-group.com |